PRODUCTS

“We produce the simplest machining piece right up to the most complex and precision piece”.

At SINAEX we manufacture a wide range of pieces of diverse sizes, materials, weights and batches, adapting to the needs of our clients.

We have a production department with specialised machinery, which enables us to apply machining techniques, organising the work process rationally so as to achieve an increase in productivity and production flexibility. This way not only do we obtain a high degree of quality, but also a quick delivery time frame.

CONTACT

Do you want to get to know us?

PRODUCT LIST

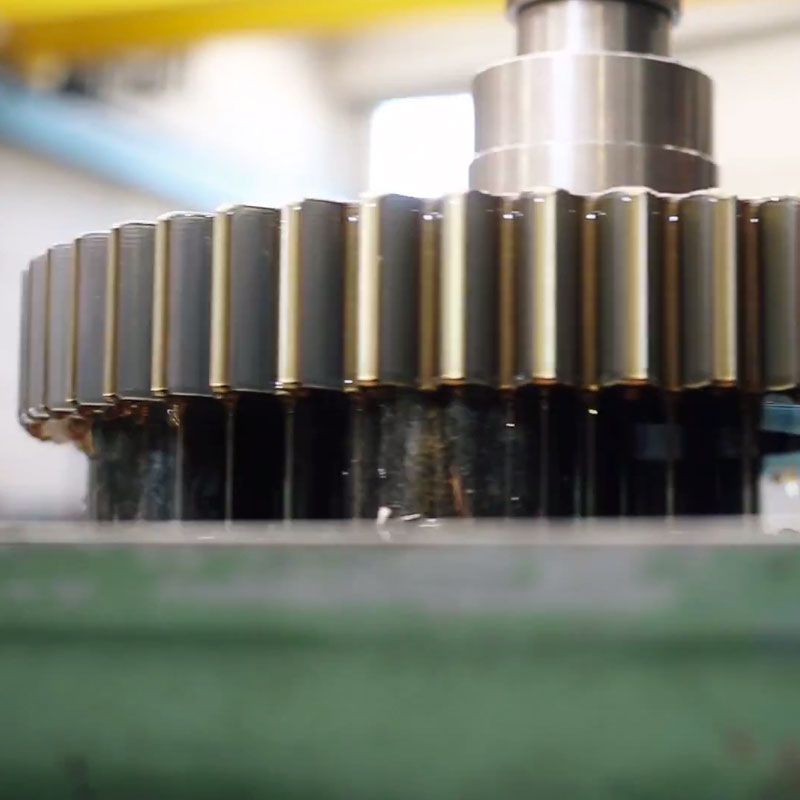

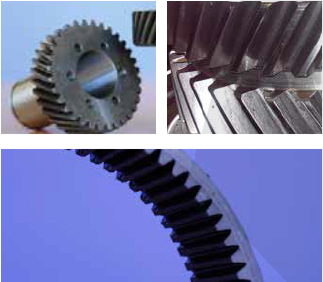

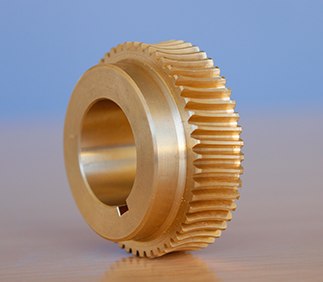

External, internal, spur and worm gears and Herringbone gear.

Diameters between 5 and 1000 mm.

Modules between 0.5 and 25.

Pitch diameter between 50 and 1.

Cutting lengths between 0 and 400 mm.

Cutting of pumping elements.

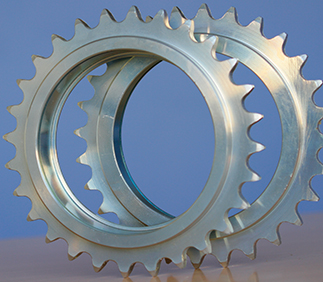

Sprockets and pulleys

Pitches up to 50.8 mm (2’’),

Pulleys for HTD, T, XL toothed belt and special pulleys.

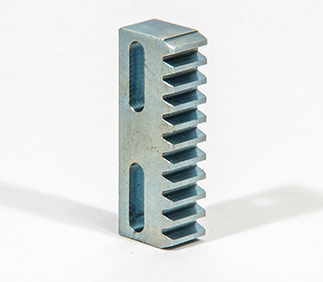

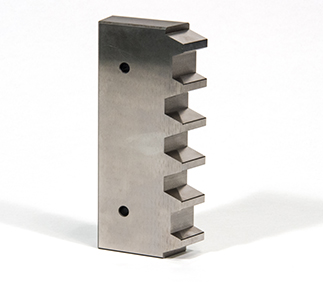

Spur and worm tooth racks.

Cutting heights up to 200 mm.

Modules between 0.5 and 12.

Sprockets and pulleys

Modules between 0.5 and 14.

Cutting with tangential system.

DIN5480, DIN5482 internal and external toothed and spline shafts.

Fellow cutting, Hobbing machine cutting and MAAG cutting.

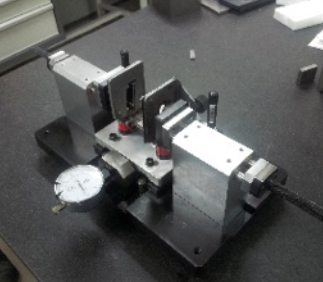

Verification and control tooling.

CNC machining maximum 800 mm.

5-Axis machining 300 x 300 x 300 mm.

Maximum grinding 900 mm.

Manufacture of cutting tools for MAAG shaping machines.

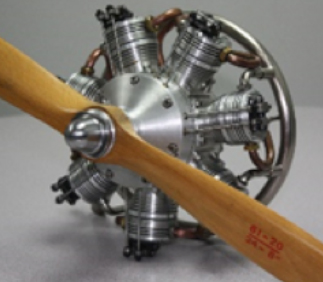

Precision machining for competition vehicles.

Assembly of assemblies and sub-assemblies.

Highly complicated parts.

Tools for brass fittings.

Stepped soldered carbide drill bits for valve manufacturing.

Profiled Widia inserts for all types of applications and sectors.

Step drill bits for aluminium and brass machining.

Widia die for tube reduction.

PRODUCTION METHODS

“Precision machining is produced using the latest generation machinery”

SINAEX has over 6,200m², distributed into 3 production centres, with 80 metal-mechanic sector professionals, responsible for adapting solutions to the needs of each client. We incorporate the most advanced technology to offer the highest precision machining, which is complemented with the latest generation verification measures.

Among the main equipment we use, the following are particularly noteworthy:

ATONDOA:

- MORI SEIKI NV 3000 DGC 5 axes electro-erosion by wire

- Charmilles CUT 200

ENPA:

- MAAG SH-75K cutter

- TOS OHA 50A cutter

INAHER:

- CNC WALTER HELITRONIC POWER grinding machine

- AMADA WASINO GLS5 optic CNC profile grinding machine

English

English Español

Español Français

Français Deutsch

Deutsch